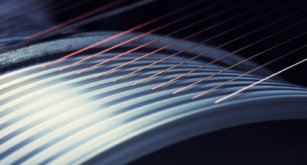

GALVANISING PROCESS AND ASSOCIATED EQUIPMENT

Read more about PWT's Payoffs for Wire Drawing solutions

Read more about PWT's environmentally friendly Gas Atmosphere Process

Read more about PWT's special galvanising preparation that eliminates the need for acid cleaning or fluxing

Read more about our unique single dip Galfan® (ZNA15%) or ZNA110% alongside the standard zinc

Read about how PWT's revolutionary EMW® and other wiping systems achieve cost per ton reductions of 25% or more

Read about how to improve efficiencies with PWT during the quench and wax process

Read about a number of cost efficient options achieved with PWT's Take-up Frame products

EMWFurther information

PadWipeFurther information

Gas GravelFurther information

Unique one-dip galvanising

Quantum™– EMW™

PWT’s Quantum™– EMW™ is an electromagnetic wiping unit capable of cost per ton reductions in zinc of more than 25%.Find out more

The Gas Gravel Wiping System

The PWT designed and installed Gas Gravel Wiping System is for galvanising operations that require a thicker layer of zinc at wire speeds normally in the range of DV 120 to DV 160.Find out more

The Gas Atmosphere Process

PWT’s environmentally friendly Sendzimir System™ prevents steel being exposed to air during the galvanising process, thereby eliminating the use of harmful chemicals and acids in the production process.Find out more

The Pad Wiping System

PWT’s pad wiping system is designed to provide a commercial grade, lightly coated wire finish – in both zinc and zinc alloy – by physically removing excess zinc during the galvanising process.Find out more

WIRE DRAWING AND ASSOCIATED EQUIPMENT

Quantum LCM

By cleaning lubricant used in the steel drawing process, PWT’s Quantum™– LCM™ achieves up 65 to 70% savings on wastage.Find out more